Multimaterial 3D Printing: Palette+ vs. Prusa MMU2

For the past six months or so I've owned a Palette+ filament splicer for my 3D printers, and a few weeks ago I received my Prusa Multimaterial Upgrade. This has given me a unique chance to compare two different approaches to 3D printing with multiple materials in a single print.

The TLDR Summary

The Palette+ works by splicing together segments of filament in exactly the right lengths to change materials at exactly the right point in the print. The Prusa MMU2 achieves the same end goal by stopping the print, unloading one filament, and loading another each time it needs to change materials.

Both approaches work, but neither is perfectly reliable. Both the Palette+ and MMU2 are slower than a single material print and will waste some material. Often they are a lot slower and waste a considerable amount of material. The Palette+ is faster than the MMU2, but the MMU2 produces less waste.

Between the two, my experience is that the MMU2 is somewhat more reliable than the Palette+, and it's less expensive; however, the soon-to-be-released Palette 2 should improve the reliability. The MMU2 only works with a Prusa MK3 printer, while the Palette+ can be used with almost any hobby-level 3D printer.

If you want to do multimaterial prints and you already own a Prusa MK3, then the MMU2 is the better choice. If you already own some other 3D printer, then the Palette is the only choice. If you don't currently own a 3D printer and want to buy one for multimaterial printing, my choice would be to buy a Prusa MK3 and upgrade to the MMU2. But whatever you choose to buy, you should be proficient in 3D printing in a single material before you try to tackle multimaterial.

Why Multimaterial?

Printing with multiple colors makes a surprisingly big difference in how the finished product looks.

3D printing is cool technology. But most hobby-level printers are limited to printing with one kind and color of plastic at a time. There are some tricks you can use to do very limited multi-color prints, such as printing a few layers then pausing to change to a different filament. But that's a nuisance and can only really do "2.5D" objects that are more bas-relief than anything else. Multimaterial printing gives you the ability to make truly multicolored things without painting or post-processing. And to be completely honest and transparent, one of the reasons I like 3D printing is because I don't have the patience to learn how to paint or sculpt well.

Beyond just colors, multimaterial printing also holds the promise of making more functional things by combining different kinds of materials in a single print. For example, you can combine flexible and rigid materials to make prints that can move and flex in ways that might be difficult or impossible using any traditional manufacturing method. And you can print your supports in a dissolvable material for easy cleanup of even the most intricate support structures. For the hobbyist, multimaterial printing is a next-level capability.

A test print combining PLA and TPU in the same object shows the interesting possibilities for making things with both rigid and flexible materials.

The Urge to Purge

There are disadvantages to multimaterial printing, too. A multimaterial printing process has a lot more complexity than 3D printing in a single material, and that means more things that can go wrong, and more tweaking and tuning to get it exactly right. If you have reached the point where 90% of your 3D prints work on the first try, it may be very frustrating to take the plunge into multimaterial and find your failure rate shoot way up.

This purge tower, produced by the Palette+, weighs twice as much as the actual print.

Even when everything is working perfectly, multimaterial printing requires a lot more time and material. Every time you change material, the printer needs to extrude a bunch of waste plastic to ensure a crisp transition to the new filament; this waste mostly gets put into a "purge tower" which you throw away at the end of the print--though you can also use some of it for infill or supports and use some other tricks to reduce the amount of waste. (If you have a printer with multiple extruders then this purge isn't necessary, but multiple extruder designs have their own problems--see below.)

Fortunately, with both the Palette+ and the MMU2 you can easily print in single material mode, so your performance for single material prints will be unchanged. From my perspective, the added capabilities of a multimaterial print far outweigh the time and waste.

The Palette Way

The Palette+ works by splicing carefully measured segments of filament together, so that the splice should be extruded while the printer is printing the purge tower. The Palette software inserts pauses into specific points in the gcode, which the splicer will detect during the print so it can stay in sync with the progress of the print.

The Mosaic Palette+ feeding into a Prusa MK3

This system of synchronization is probably the weakest part of the Palette+ design. There's a long filament path between the splicer and the extruder, and small errors in tracking the print progress can lead to the splice hitting the extruder early or late, causing very visible stripes of the wrong color in the final print. Even after six months of tweaking and tuning my Palette+, large prints (ones with more than 500 or so material changes) will almost always have at least one visible defect.

A major revision to the Palette was recently announced, the Palette 2, which will address these problems by making the filament path shorter and using a new control unit, the Canvas Hub, to keep the splicer synchronized with the print.

The other major shortcoming of the Palette is the fact that it relies on splicing together segments of filament. I've found that while the splices usually hold, I will occasionally have a splice inexplicably break in the middle of a print. When this happens there's no way to recover, you have to start the print over from the beginning. You're also limited to combining materials which will fuse together well: I've had good success combining PLA and TPU in a single print, but some material combinations won't be possible.

The Prusa Way

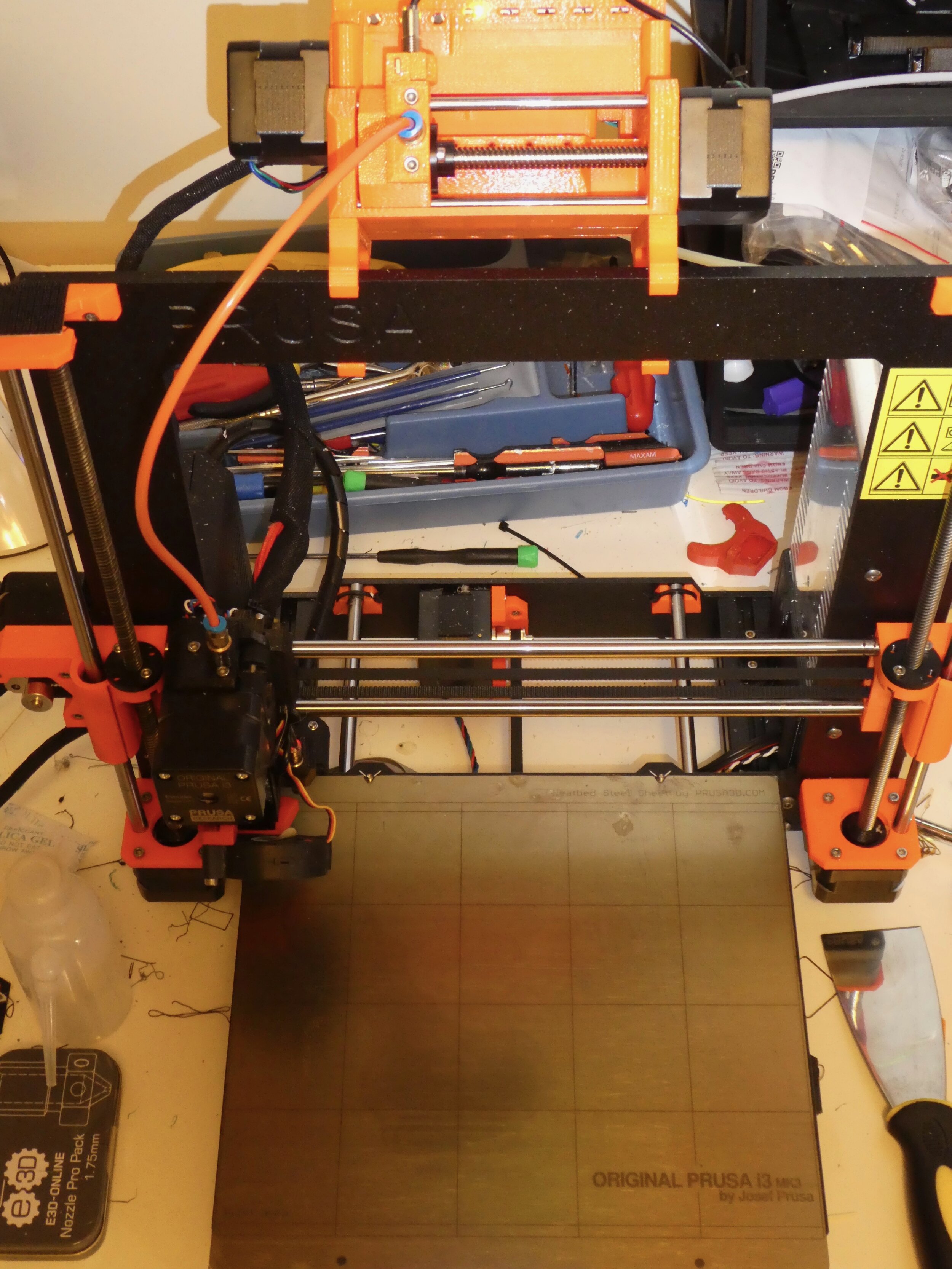

Prusa's new Multimaterial Upgrade 2 for the Prusa MK3 takes a completely different approach. The MMU2 sits on top of the printer and is effectively an automatic filament loader/unloader. When the printer needs to change materials, the print pauses while the MMU2 retracts the old filament, then loads the new filament in the extruder. The printer does some purge to ensure a clean transition, but less purge than the Palette, because most of the old material was removed in the unload process.

The orange unit attached to the top of the Prusa MK3’s frame is the MMU2.

This process is slow: it takes over a minute to go through the complete unload/load/purge cycle, while the Palette+ takes 30-45 seconds to finish changing materials. But there are no splices to break, which gives more flexibility in the kinds of material you can combine in a single print. And the MMU2 never gets out of sync with the print, so you never get stripes of the wrong color.

The MMU2 is brand new, and as of this writing has only been shipping for a few weeks. There are some "barely out of beta" problems with the early units, but my experience is that my prints with the MMU2 are as reliable, maybe more reliable, than the best I was able to achieve with the Palette+. I expect that as the bugs get fixed the MMU2 is likely to become much more reliable than the Palette+.

Probably the biggest drawback to the MMU2 is that it only works with the Prusa MK3 printer. The MK3 is an outstanding printer, perhaps the best in its class, but not everyone has or wants an MK3. The other drawback to the MMU2 is that it's only available as a kit which you have to assemble, whereas the Palette is fully assembled and (mostly) ready to go.

Why Not Multiple Extruders?

There's several 3D printers available with two, three, or four extruders. I've never owned a multi-extruder printer, but based on what I've heard from people who do own them I'm not a fan of this approach.

Putting multiple extruders on a 3D printer adds a lot of cost and complexity, and in the end the results are often mediocre. Getting good print quality requires aligning all the print nozzles with a high degree of precision. Even if you succeed, it's likely that the idle extruders will ooze plastic and drag it around unless you have some mechanism to physically move them out of the way--and that means even more cost and complexity.

The people I know who own multiple-extruder printers have mostly given up on getting it to work well, and just use their printers in single extruder mode.

That said, there are advantages to multiple extruders. Perhaps the biggest is that using multiple extruders eliminates the need to purge when changing materials, so you don't have the same cost in time and wasted materials for doing multimaterial prints.

Which is Better?

Speed: Palette+, which takes about half the time to change materials as the MMU2.

Waste Material: MMU2 wastes about half the material as the Palette+.

Reliability: Slight edge to the MMU2. Both suffer print defects and failures too often to be true workhorses, but I think the MMU2 approach is inherently more reliable since it doesn't require splicing two pieces of filament together. The Palette 2 should address some of the worst problems with the Palette+, but the MMU2 should also improve a lot in the coming months as the early bugs get worked out.

Capability: MMU2, because the MMU2 can accept five different materials to the Palette's four, and the MMU can print with combinations of materials that don't fuse easily or at all.

Initial Setup: Palette+, which requires only a little calibration. The MMU2 is only available as a kit, and requires major surgery on your printer.

Compatibility: Palette+ works with almost any 3D printer, while the MMU2 only works with Prusa printers.

Software and Toolchain: MMU2. The Palette+ requires an extra step to post-process your gcode, and the Chroma software for post-processing tends to give mysterious "out of memory" errors on my Mac. Mosaic Manufacturing, makers of the Palette, are coming out with their own cloud-based slicer which will avoid the post-processing, but I'm skeptical that it will ever be as capable as the more mature slicers (plus if they ever go out of business the cloud-based slicer won't be available). Slic3r, the free slicer supported by Prusa, has extensive MMU support, and other slicers are starting to support it, too.

Support: Tie. Both Prusa and Mosaic have excellent support and online communities, though the Prusa forums are considerably larger and more active.

Cost: MMU2. Even though the price of the Palette 2 will be much less than the Palette+, the MMU is even less expensive.

Parting Shots

Multimaterial printing is definitely still varsity-level 3D printing, no matter what equipment you buy. I think it's worth the effort for the extra capabilities, but if you're not willing to invest the time to really learn how to use your tools you may find it frustrating.

If you're trying to decide what to buy, I have a very simple decision tree:

If you already own a Prusa MK3: Buy the MMU2. It's cheaper, more reliable, and more capable.

If you already own some other printer and don't want to buy a new one: Buy the new Palette 2. Also buy the Canvas Hub, which is technically optional but realistically a requirement for most users if you want good results.

If you are looking to buy a new 3D printer with multimaterial capability: Buy a Prusa MK3 and the MMU2, unless there's some must-have capability you need that Prusa doesn't offer (like a larger print volume).